As one kitchen’s coming off the machine, the next one’s leaving the screen and the process starts again.” And it all helps to keep the production workflow running smoothly. Even if we’re just doing a simple frame and carcass drawing, it goes through the software. “Cabinet Vision is the future of Crabtree and Hargreeves.

#Cabinet vision solid 4 code

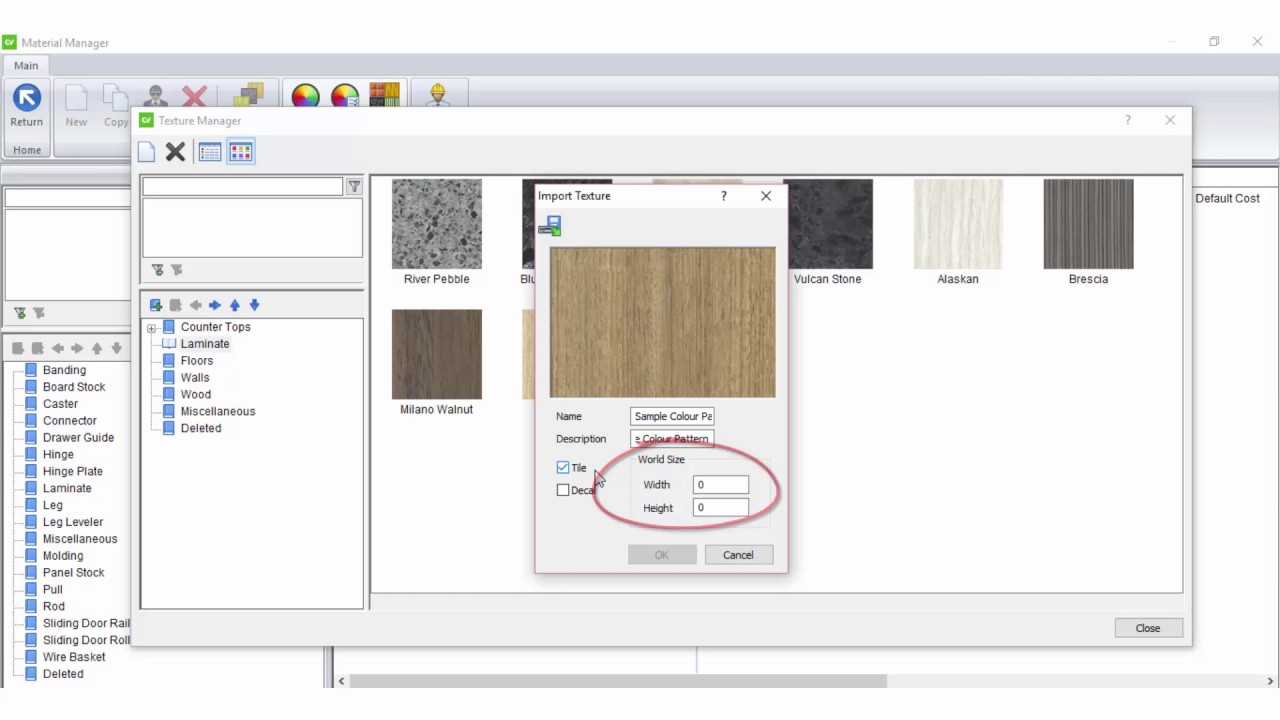

“Once the design is finished, we simply send the NC code to the machine, using Screen2Machine, and once it’s gone from the computer to the machine there’s no scope for any errors.”Īnd he says while just one person can run the Felder, their production throughout the day would be the equivalent of three or four people. Now the entire process takes about a day and a half. And after that, it was about a week to get everything cut and fully machined, drilled, and hinge holes and screw holes for runners cut, and ready for assembly. “When we were using the panel saw, it used to take a day to produce cabinet cut lists for one kitchen. “Instead of the fitters cutting out where plug sockets go inside cabinets, we set it up onscreen and the machine simply cuts them.”Īs well as accuracy, Cabinet Vision also provides considerable time savings, increasing their capacity and enabling them to take on additional business. He says they also use it for plug cutouts. Everything’s completely customisable – doors, drawers, bore holes the list is endless.” Double clicking brings them up into section mode, and we break everything down. Then we drag the objects into the room, to wherever we want them. “When we start a new job in Cabinet Vision we put all the customer’s details on the Job Page, and set the specification which includes everything such as the carcass material, frame type, hinge type, and construction method – we normally use the blind dado method for everything we do, wherever possible. His son, Bradley, handles the manufacturing operation on the machine.

#Cabinet vision solid 4 software

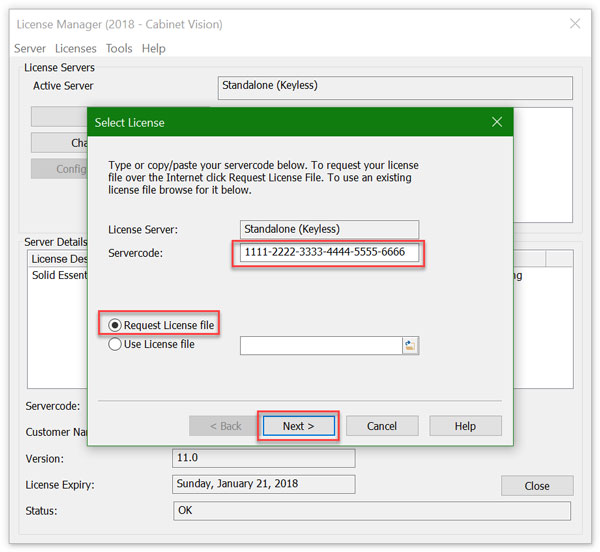

“They have state-of-the-art computer skills, and using the software makes them extremely valuable employees with a different skill set from traditional craftsmen.”īrandon is the company’s main designer using Cabinet Vision, which also creates NC code sent to the Felder through the software’s Screen2Machine module. But he says Cabinet Vision means it doesn’t have to be. While Brandon Collins’ background is in cabinetry and woodworking, his team is not all from a cabinetry background.

It eradicates all errors, as the design is faithfully reproduced in the NC code.” They helped us every step of the way, and recommended Cabinet Vision as the best software for driving the machine to do what we needed. Felder understood that this was our first CNC machine and that we had no experience of them. This prompted us to go down the CNC route. “The issue we had was that even if we were just 1mm out with a couple of parts on the panel saw it added up to a product that wasn’t accurate. Until investing in a Felder Format 4 Profit H08 machine tool with 10ft x 5ft bed size, designs were done in SketchUp, and what he describes as ‘crude cutting lists’ were then created with plug-ins, to use with its panel saw. The Essex-based company is a recent convert to CNC machinery and CAM software. Those are the words of Brandon Collins, owner and managing director of quality kitchen specialist Crabtree and Hargreeves. “Cabinet Vision turns people who are unskilled in the craft of woodworking, into valuable, core members of staff, doing what used to be a highly skilled job.”

0 kommentar(er)

0 kommentar(er)